Question: What is the development direction of stone machinery today?

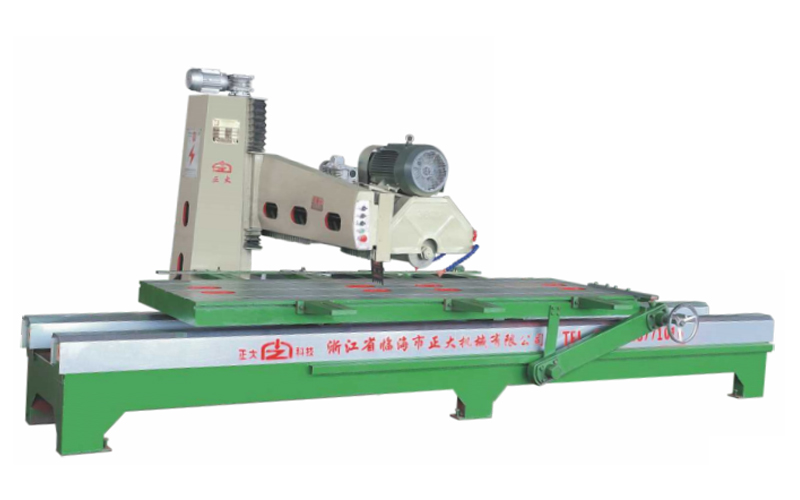

Answer: The general trend of the development of mechanical engineering science will be digitalization, intelligence, refinement, miniaturization, life and ecology. Stone machinery, as a branch of mechanical engineering discipline, also follows this general trend of development towards robotization and intelligence. The development of economy and the progress of society have new requirements and hopes for stone machinery.marble cutting machine Wholesales

Based on the summarization of stone machinery and computer skills and network skills, a digital development trend has been formed. Stone cutter waterjet is equipped with high skill content and high integration. The overall level of China's waterjet is still far from the international advanced level. Opportunities and challenges coexisted on the journey towards making a powerful country with an arc polisher. The product's ability to depict innovation has become the primary element of the resolution company's position in the global competition. The development of large-scale stone machinery, there is no experienced experience to learn, so it is necessary to rely on the integration of multi-disciplinary skills to improve the depiction of power and quality, our company's ability to independently differentiate and compete in shopping malls.

Question: There are a lot of stone cutting machines on the market, all kinds of colors, and the quality is also uneven. How to buy stone machinery to buy it at a good price?

Answer: 1. The stone cutting machine runs for one minute after being powered on, and it should be held by hand during operation. The hand should not notice any abnormal tremors. Investigate the commutation spark. The commutation spark should not exceed level 3/2, usually Looking from the air inlet of the thing, there should be no significant arc on the appearance of the commutator. During operation, there should be no abnormal noise.

Second, check the nameplate and clarification of the stone cutting machine, the nameplate parameters should be common with the 3C certificate. Clarify that there should be specific addresses and contact information of the manufacturer and manufacturer on the book. The batch number of the product traceability shall be on the nameplate or certificate of conformity.

3. Investigate the outer packaging of the stone cutting machine. The outer packaging should be clear and not damaged. Open the box to investigate the appearance of the stone cutting machine. The color should be uniform. The plastic parts should have no obvious shadows and dents, and should not be scratched. There are marks or bumps, the installation dislocation between the shell parts is ≤0.5mm, the aluminum casting paint is lubricated and beautiful without defects, and the appearance of the whole machine should be free of oil stains and stains. When you hold it with your hands, you feel better about yourself, and the handle of the switch should be flat. The length of the cable should usually be no less than 2 meters.

Back to superior news