A stone processing machine is a tool used to cut stone into pieces. There are several types of stone cutting machines, including manual and CNC. Manual cutting involves a lot of work and is prone to size errors. Semi-automatic cutting machines are often more efficient and can significantly reduce labor costs, but they are less suited for small-scale productions.

Stone Processing Machines are used in many different applications, including the fabrication of masonry, building materials, and more. They sort stone, earth, and other solid materials, including unhardened cements, ceramic paste, plastering materials, and more. They can even be used to create moulds for foundries.

Technological advancements help create more accurate stone processing machines. They reduce processing time and material wastage. A number of manufacturers invest in R&D to provide innovative products to end users. The demand for stone processing machines is increasing globally. A recent report from Technavio revealed that the global stone processing machine market is a moderately fragmented market with a few well-established vendors and many smaller regional and local players. Most manufacturers of stone processing machines focus on new product launches, expansions, and strategic acquisitions.

A stone router is another option that can be used for stone processing. This machine is capable of applying full polish to stones and can automatically cut complex edges and angles. Some of these machines have a CNC saw built into them, which makes them even more versatile. They can even cut full slabs before routing them to a final shape.

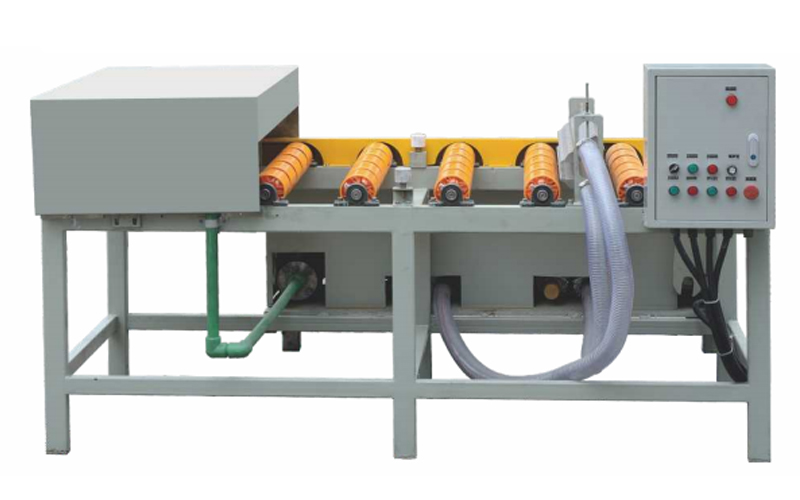

HIGH PRESSURE CLEANNING AND DRYING MACHINE ZD-TMGX

| Item |

ZD-TMGX |

| Water consumption |

3m³/H |

| Water pumps power |

2.2kw |

| Transmission power |

0.4kw |

| Outline dimension |

2000×1500×1200mm |

| Weight |

0.5T |

| Fans power |

4kw×2 |

| Total power |

10.6kw |