1. Always check the equipment, including the straightness of the steel belt, the track and the verticality of the machine, and pay attention to clean the dust inside the machine;

2. The guide rails should be cleaned and lubricated and re-oiled frequently to remove dust and other debris to ensure that the equipment operates normally and is well maintained. The rack should be wiped frequently and lubricated to ensure lubrication without debris. The motor also needs to be cleaned and lubricated frequently, the machine will be able to move better during cutting, more accurate cutting, and the quality of the cut product will be improved.

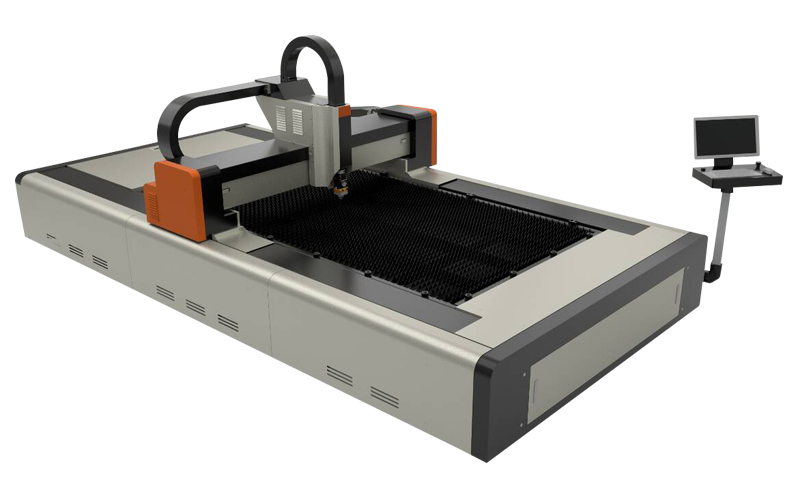

3. The laser cutting head is a fragile item on the laser cutting machine. If it is used for a long time, the laser cutting head will be easily damaged, and it should be checked and repaired regularly. If there is deformation or other forms, you should know that the laser cutting head has been damaged a little at this time, and you need to replace it. Failure to replace will affect the cutting quality and increase the cost, and some products may need to be reprocessed to reduce production efficiency. The laser cutting head should be produced by a professional manufacturer or imported from a foreign country. Please check carefully when you know the purchase to avoid problems when using it.Fiber Laser Cutting Machines Suppliers

The equipment needs excellent maintenance and maintenance, and the better its performance, the cutting quality is reliable when the cutting process is performed, and the service life is longer. From this perspective, the production cost of the laser cutting machine without maintenance is greatly reduced.