There are several types of laser cutting machines available in the market. The CO2 laser is commonly used for cutting soft materials, such as plastics and rubber, while fiber laser is commonly used for metal and aluminum cutting. These machines are highly accurate and can cut even the most intricate contours. These cutting machines require minimal human intervention during the process, which greatly reduces the risk of accidents. Laser cutting is becoming increasingly popular in many industries and is used by numerous organizations to cut complex shapes.

These laser cutting machines produce clean, high-quality cuts without requiring extensive secondary processing. However, the edges of the parts are work-hardened, which is not ideal for some applications. This surface treatment also adds time and money to the overall processing process. Laser cutting machines are becoming increasingly popular in industrial manufacturing environments. In addition, they can produce intricate parts without the need for custom tooling. However, there are some disadvantages to laser cutting.

Aluminum is highly reflective, which can damage the laser and its beam delivery optics. In addition to damaging the laser, aluminum can also damage the laser itself. Inefficient cutting with a laser can cause a molten pool to form on the surface. Even a non-reflective coating won't solve this problem. Instead, manufacturers should use a system that detects the excess radiation and stops it before any damage is done to the material.

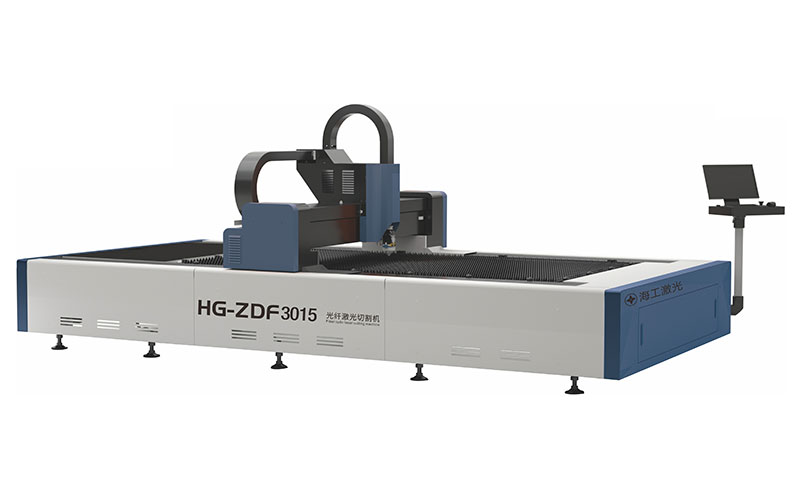

An industrial-grade maintenance-free laser cutting system has outstanding technical advantages, such as high precision and repeatability. Unlike other laser cutting machines, the industrial-grade maintenance-free system also saves on operating costs. The precision of the laser cutting process will also increase with more advanced machines. The automation of these cutting machines will allow them to operate around the clock without human intervention. A safe environment for laser cutting technicians will be created in such a setting.

Fiber lasers work similarly to fiber optic lights. A laser beam enters a tube coated with a special type of glass. This glass absorbs the light and bounces down the tube. The light increases in strength as it goes down. The special properties of fiber laser light make them easy to absorb by reflective materials, which gives the ability to cut with great detail. In addition to metal, fiber lasers can cut materials up to 3D curved shapes.