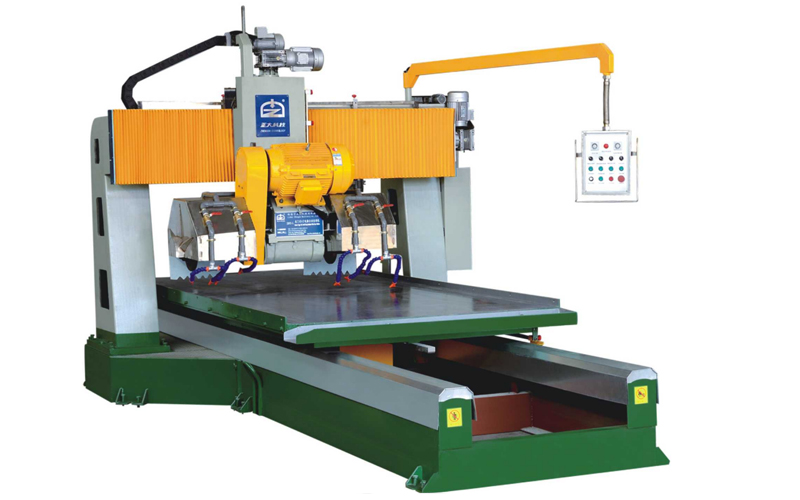

There are several types of stone profiling machines. These machines can be either hydraulic or mechanical and are designed to profile stone with an alternating angle. The machining process is performed by a cutting head mounted on a movable beam. Each of these stone profiling machines has different characteristics. Here are some of the common ones:

Automatic stone profiling machines are capable of processing a variety of materials, including granite, marble, limestone, and slate. They can produce finished workpieces that measure three meters by 1.3 meters. Automatic stone profiling machines utilize an optical fiber probe to accurately determine the stone's profile and automatically cut the appropriate shape with a circular diamond blade. The machine can be adjusted to the desired speed depending on the type of material and the stone's thickness.

The most common stone profiling products are three-dimensional portraits, animals, plants, and sculptured columns. These can be symmetrical or asymmetrical in shape. Stone profiling machines can cut these shapes accurately and consistently. Depending on the workpiece, three-dimensional profile products are produced by translating a tool along a rotary body. This rotary motion is necessary in order to achieve an even level of precision and consistency.

| Item |

ZDFX-L |

| Table size |

3000×1580mm |

| Blade diameter |

Φ350-Φ600mm |

| Main engine power |

18.5kw |

| Outline dimension |

5800×2400×2000mm |

| Weight |

4.5T |

| Total power |

21.3kw |

| Water consumption |

4m³/h |