A bridge edge grinding machine is a specialized tool used to grind the edges of bridge decks, girders, and other structural elements. It consists of a machine frame that holds a grinding wheel or another abrasive tool, which is used to remove material from the edge of the structure.

Bridge edge grinding machines are typically used to remove burrs, rough edges, or other imperfections from the edges of bridge decks and girders. They are often used in the construction and maintenance of bridges and other structures and can be used to prepare the edges for welding, painting, or other treatments.

Bridge edge grinding machines are typically large, heavy-duty machines that are designed to withstand the rigors of the grinding process. They are often equipped with safety features such as guards and emergency stop buttons to prevent accidents.

There are several types of bridge edge grinding machines available, including manual and automatic machines, which are designed to suit different application requirements. They are also available in a range of sizes and configurations and can be customized with different grinding wheels and other features to suit specific needs.

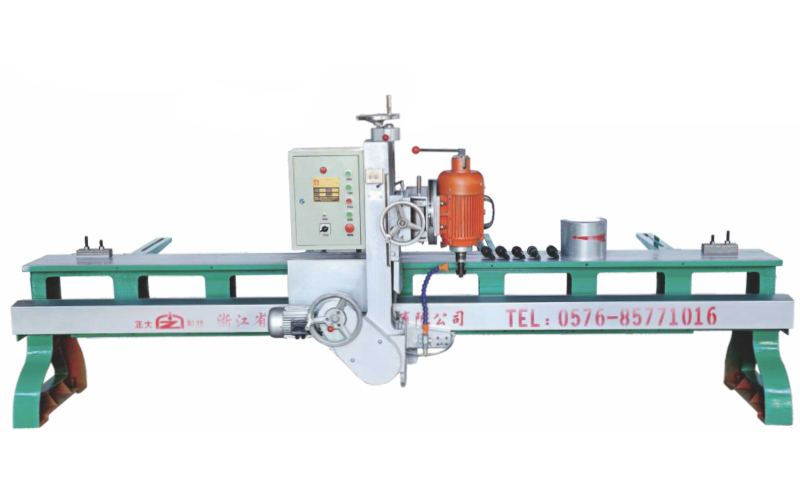

EDGE GRINDING MACHINE ZDM99-B

| Item |

ZDM99-B |

| Straight line edge grinding length |

2900mm(3300mm) |

| Curve line length |

2300mm(2600mm) |

| Main engine power |

5.5kw |

| Total power |

6.05kw |

| Water consumption |

2m³/h |

| Mainshaft |

Φ30mm |

| Outline dimension |

3600×1600×1500mm |

| Outline dimension |

(4000×1600×1500mm) |