A bridge edge cutting machine is a special tool used for cutting the edge of a stone slab. The machine has an automatic operating system and a fabricated trolley. The machine has a cutter size of 12' to 24' and can be moved vertically and horizontally. The machine can be used for cutting edges of natural stone slabs. It is also called a Design Machine. This type of cutting machine is fully automatic and can be used to cut different designs in natural stone.

The Bridge Edge Cutting Machine is made of resistant welded steel and is available with two, three, or four motorized axes. It features a PLC touchscreen for programming. The machine has a rack with sliding linear bearings for transverse movement, while the spindle slides on two vertical guides. The spindle is manually inclinable up to 90 degrees. It has a rotating head and can also perform special corner cuts and recesses.

The Bridge Cutting Machine is a versatile machine that is widely used in construction, decoration, and water environmental protection. It is suitable for a variety of cutting projects, including stone bridges, core samples, and laboratory stone processing. It has many features, including an automatic hydraulic tensioning saw to improve the service life of the saw blade, a compensation device to keep the plate flat, and a frequency converter step-less speed regulation to adjust the cutting feed speed.

A bridge edge cutting machine is a powerful piece of equipment for cutting stone slabs. It can cut granite, marble, ceramics, and many other types of slabs with precision. It is often used to cut slabs after primary sawing. There are many different types of bridge saws, including manual ones and automatic ones. The 5-axis bridge saw is the most advanced and powerful and can cut a stone at any position around its vertical axis.

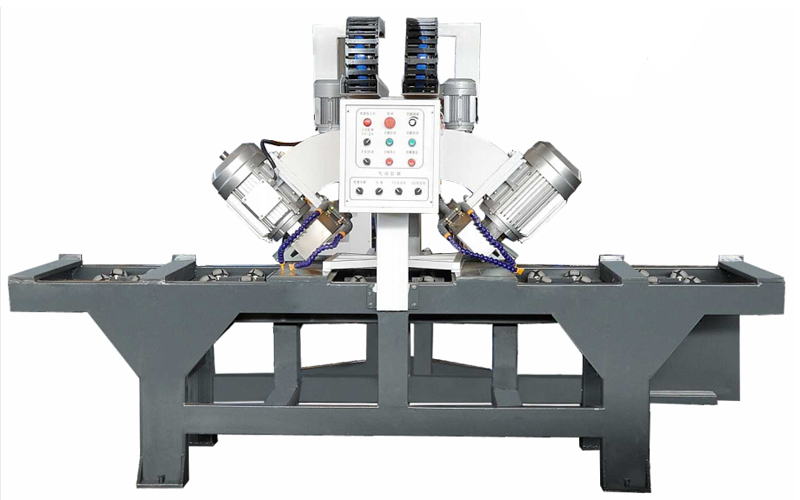

CHAMFER CUTTING MACHINE FOR BOTH SIDE ZD-TM2500B

This machine is designed focused on the countertop double side chamfer cutting.

With the double machine head chamfering, the workpiece is fixed, saw blade running, in high precision to avoid different size.

Suitable for processing line, use roller table to make the input and output slab to be more convenient.