A stone profiling machine, also known as a stone edge profiling machine or a stone edge polisher, is a machine that is used to shape and polish the edges of natural stone tiles, slabs, and countertops. These machines can be used to create a variety of different edge profiles, such as beveled, bullnose, ogee, and waterfall edges.

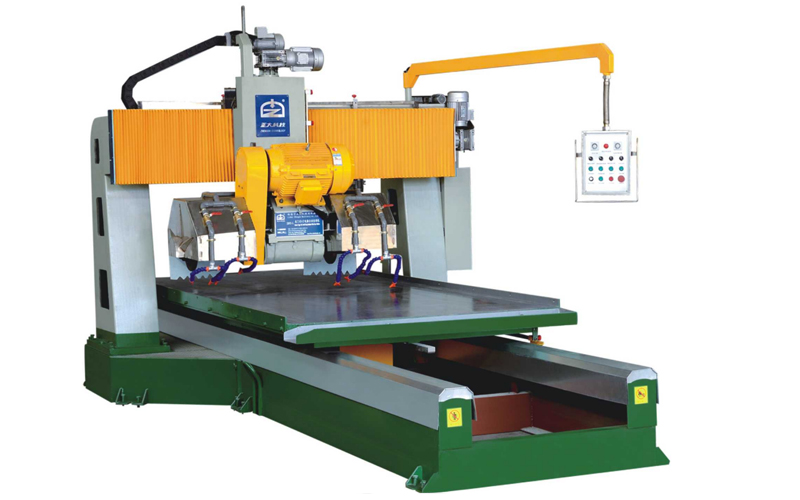

The machine typically consists of a base or worktable on which the stone is placed, as well as a series of rotating diamond-tipped blades or grinding wheels that are used to shape and polish the edge of the stone. Some machines may also include water jets or a built-in dust collection system to help cool and lubricate the blades and to minimize dust and debris.

There are a variety of different types of stone profiling machines available on the market, with different features and capabilities. Some are manual machines that are operated by hand, while others are fully automated and computer-controlled. Some machines are designed for use with specific types of stone, such as granite or marble, while others can be used with a wide variety of different stone materials.

When choosing a stone profiling machine, it's important to consider the types of stone you will be working with, as well as the specific edge profiles and finishes you need to create. It's also important to consider the size and weight of the stone pieces you will be working with and to choose a machine that is capable of handling the size and weight of your stone.

It's also important to consider the machine's power, speed, and precision. Some machines are designed for high-volume production, while others are better suited for small-scale or custom projects. It's also important to consider the machine's maintenance requirements and costs.

FEATURE AND FUNCTION

This machine is the latest design for processing the special -shaped stone material.

It adopts portal structure to make the Max. width of 1580MM, and it can make 4PCS of lines in one time processing.

It also can make the square column with the length 750MM in two lines.

It adopts the double triangle in the rail.

It has long using life with high efficiency which put the gear under the table.