1. Transfer the damaged location

Move the severely damaged place to a secondary position to protect the service life of the sealing surface and the throttle surface of the valve seat. Usually, the ceramic ball valve has the most serious erosion, and the fastest fluid velocity is the lower part of the fluid inlet. Since the ceramic ball valve has a three-piece structure now, the ball core can be reversed for use. In this case, a ball core can be used four times at the inlet, ie: the life of the valve is extended by 4 times.

2. Cleaning the pipes

Since the debris in the pipeline is blocked or stuck at the guide part of the orifice and the valve core is broken, it must be disassembled and cleaned to remove the slag. If the sealing surface is damaged, it should be ground. At the same time, the bottom plug should be opened to flush Remove debris and flush lines.

3. Increase the opening degree

When using a ceramic regulating valve, try to work at the maximum opening, so that the erosion, wear, and other damage of the initial impurities in the pipeline can occur outside the damaged part of the valve core. After removing the impurities in the pipeline, adjust the opening of the regulating valve to a position slightly larger than the normal opening. In this way, the entire valve core can be fully utilized until the root of the valve core and the sealing surface are damaged and cannot be used.

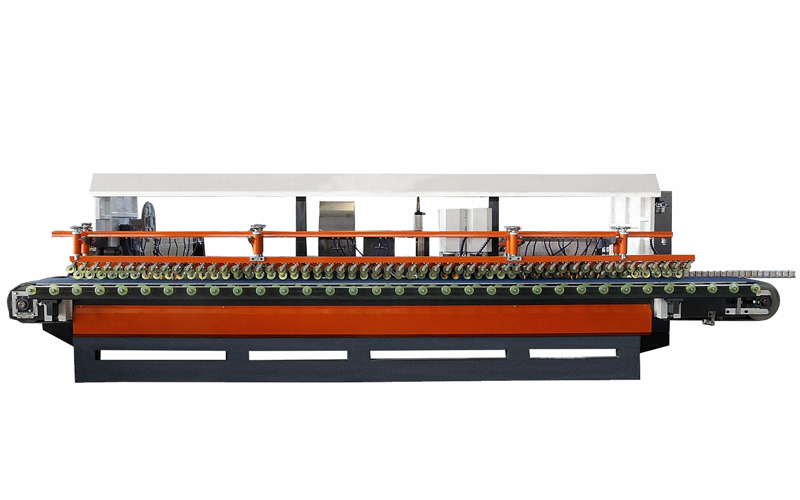

It should be noted that the grinding head of the arc polishing machine has automatic and manual modes. The life of the grinding head is about 5-10 hours. Pay attention to check whether the grinding head is still there. The conveyor belt motor and the size-adjusted motor need oil maintenance every three months, and the grinding head spindle is turned on every day to add a little oil to it. The machine tool needs to be leveled and fixed.