Before work

1. Wear work clothes and goggles. The female worker has long hair and puts on a work cap.

2. The power switch, the tightness of the saw blade, the saw blade guard, or the safety baffle should be checked in detail. The operating table must be stable, and there should be sufficient lighting for night operations.

3. Turn on the main switch, make a few laps with no load, and allow it to start after confirming safety.

When working

1. It is strictly forbidden to wear gloves. If dust is caused during operation, wear a mask or face shield.

2. Do not attempt to see small workpieces that are not clamped.

3. This cutting machine is only allowed to cut profiles.

4. Do not perform powerful sawing operations, and make the motor reach full speed before cutting.

5. No one is allowed to stand behind the saw. Either hand or arm raised.

6. Do not operate when the shield is not in place, and do not place your hands within 15 cm from the saw blade.

7. Before repairing or replacing accessories, the power must be cut off and the saw blade stops completely.

8. If any abnormal sound is found, the inspection should be stopped immediately.

After work

1. Turn off the main power

2. Clean and organize workbenches and venues

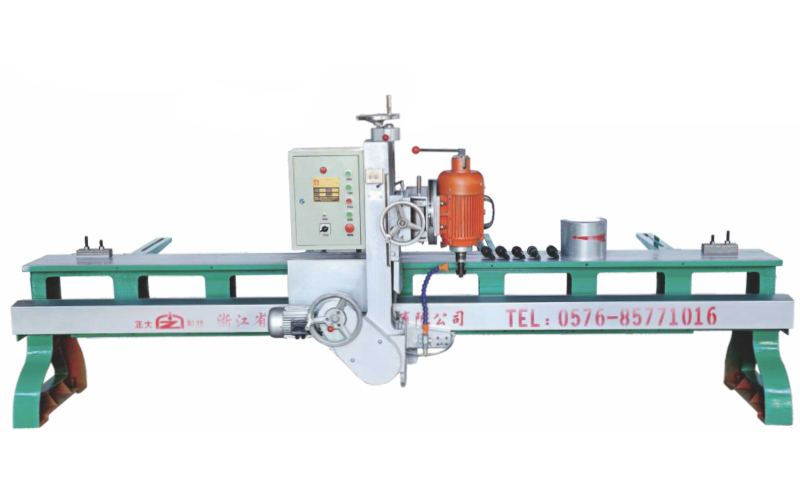

| Item |

ZDM99-B |

| Straight line edge grinding length |

2900mm(3300mm) |

| Curve line length |

2300mm(2600mm) |

| Main engine power |

5.5kw |

| Total power |

6.05kw |

| Water consumption |

2m³/h |

| Mainshaft |

Φ30mm |

| Outline dimension |

3600×1600×1500mm |

| Outline dimension |

(4000×1600×1500mm) |

| Weight |

1.0T(1.1T) |