1. Do a good job in cleaning and cleaning the parts. Cleaning includes removing residual foundry sand, rust, chips, etc. Especially for some important parts, such as gantry cutting machine, the inner cavity should be coated with anti-rust paint. Oil stains, rust or attached chips on the parts can be cleaned with diesel, kerosene or gasoline as a washing liquid, and then dried with compressed air.

2. The mating surfaces generally need to be lubricated before mating or connecting. Especially the bearing parts in the headstock parts and the screw nut parts of the lifting mechanism.

3. The matching size of the matching parts should be accurate, and the matching size should be re-checked or sampled during assembly. For example: the matching part between the journal of the main shaft and the bearing, the hole and the center distance of the matching hole between the main shaft box and the bearing.

4. The assembly of the wheel requires that the axis lines of the two-toothed wheel must be in the same plane and parallel to each other, and a normal tooth gap should be ensured, and the axial misalignment should be ≤ 2MM.

5. The joint surface of the joint should be checked for smoothness and deformation, otherwise it should be trimmed and burrs should be removed to ensure that the joint surface is in close contact, flat and not skewed.

6. The seal should be pressed into the sealing groove in parallel, and it should not be twisted and deformed, and the sealing surface should be damaged and scratched.

7. The assembly requirements of the pulley are that the axes of the two pulleys must be parallel, and the center of the pulley groove should be positive. If the offset is too large, the tension of the pulley will be uneven, causing the belt to slip and accelerate wear. At the same time, the V-belt should be selected before assembly, and the length should be the same to prevent vibration during transmission.

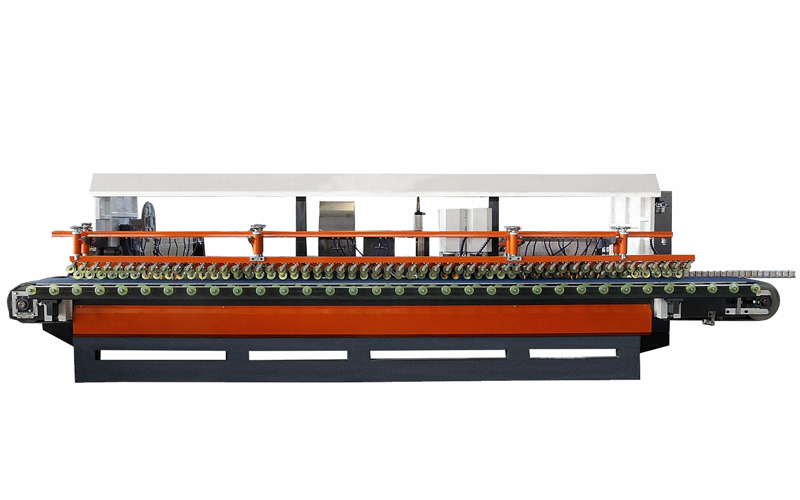

| Item |

ZD-TM2500Y |

| Processing length |

Continuous |

| Processing width |

600-2500mm |

| Processing thickness |

≤60mm |

| Processing speed |

0.5-2.5m/min |

| Dia of grinding wheel |

Φ200mm |

| Polishing head diameter |

Φ100mm |

| Total power |

25.3kw |

| Water consumption |

10m³/h |

| Air consumption |

45L/min |

| Outline dimension |

6200*2000*1800mm |