The laser cutting machine uses a laser to replace the t […]

The laser cutting machine uses a laser to replace the traditional solid cutting knife. It has the characteristics of high accuracy and high cutting efficiency, not limited to the variability of the cutting style, automatically optimizing the cutting layout, saving materials, cutting smoothly, and low processing cost. It will gradually change or replace traditional material processing equipment. As the most popular industrial laser cutting equipment in the 21st century, its processing materials have a wide range of powerful functions, and are gradually introduced into major industries, becoming a very powerful and good helper in production.

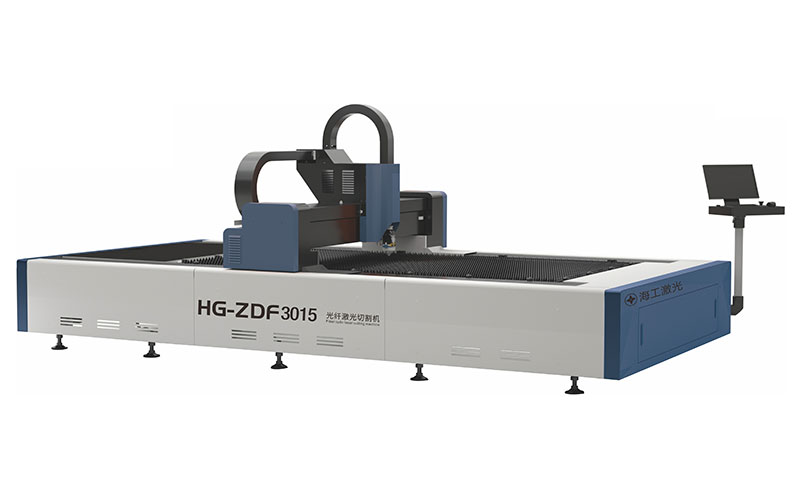

There are currently three main types of laser equipment applications. One is used for automotive sheet metal processing, transformer boxes, fitness equipment, etc. These materials are usually relatively thin. Stainless steel plates with a thickness of 1-5 mm can be cut with a medium-power laser cutting machine. Yag laser cutting machine or 500 watt fiber laser cutting machine can be used to cut this type of material. The second category is to cut plastic (polymer), rubber, wood, paper products, leather and natural or synthetic organic materials. Since this material is not a metal product, the absorption of laser light is different, it is best to use a CO2 laser cutting machine to cut this material. The third type is low carbon steel with a thickness of 8-20 mm and stainless steel with a thickness of 12 mm. This material requires a high-power laser cutting machine to cut quickly and instantaneously. You can consider buying a high-power fiber laser cutting machine. Therefore, when choosing laser equipment, we must not only consider the characteristics of our products, but also the performance and life of the laser configuration, so that we can buy the most cost-effective laser equipment that is most suitable for our industrial products.

There are many laser cutting equipments now. There are different laser cutting machines, such as CO2 laser cutting machine, fiber laser cutting machine, precision laser cutting machine, etc. Not only are the lasers used are different, but there are also big differences in use. Different materials have different characteristics, and their degree of absorption of different kinds of lasers is also different. Some materials can absorb laser light in this band, but cannot absorb laser light in other bands, which makes us choose laser equipment based on specific material characteristics. For items of different thickness, size and shape, different laser equipment will be used during the processing to obtain better processing results.

Zhejiang Haigong Machinery Co., Ltd. is famous China Laser cutting machines Manufacturers and Laser cutting machines factory, set up in 1978 and it is located in TAIZHOU, a coast city in the Yangtze delta with an advanced economy and convenient transportation. We are always a global leader in stone processing machinery as our lifelong goal. We have been devoted to developing and producing various stone machinery for more than 30 years of history. Now with an area of 80,000 square meters, intelligent office building and 50,000 square meters modern standard factories contain welding, casting and another three production areas. It has become a high technology enterprise at the command of research, manufacture, selling and after-sales service to produce stone machinery professionally. We were awarded as one of the Top ten of CISE Chinese stone machinery, and also one of the ten top brands among Chinese stone machinery, and also passed CE certification and so on. Our major products are infrared bridge cutting machine, PLC automatic profile cutter, bridge edge grinding machine, bridge edge cutting machine, edge cutting and grinding machine and also wholesale Laser cutting machines, line polishing machine, automatic washbasin polishing machine and so on which made by our under-company: ZHEJIANG HAIGONG MACHINERY CO.,LTD” with all the brand of ZHENGDA”.

ZHEJIANG HAIGONG MACHINERY CO., LTD.

EN Mobile Version

CN Mobile Version