(1) Good beam quality output from stainless steel polishing machine, including the stability of mode and mode;

(2) Whether the output power of the stainless steel polishing machine is large enough (this is the key to speed and effect) and whether the energy is stable (usually 2% stability is required, and 1% in some occasions, so that the ideal effect can be processed);

(3) The stainless steel polishing machine should have high reliability and should be able to work continuously in harsh industrial processing environments;

(4) The stainless steel polishing machine itself should have good maintainability, fault diagnosis and interlocking functions, and the downtime should be short;

(5) The operation is simple and convenient, and the function of the control keys is clear, which can reject illegal operations and protect the stainless steel polishing machine from damage.

Principles to be followed when purchasing stainless steel polishing machines: Stainless steel polishing machine technology has many valuable features. However, specific to whether a product is suitable for adopting this technology, the following principles should be followed:

(1) It can't be solved by other existing methods, it can only be solved by polishing;

(2) It can be solved by other existing processing methods, but if the polishing processing method is used, it can greatly improve product quality, increase production efficiency, and significantly increase economic and social benefits;

(3) Full consideration should be given to the matching links in the processing process that are related to polishing;

(4) Pay attention to the application of combined polishing processing and conventional processing technology in order to make full use of their respective strengths;

(5) In practical applications, if the economy is not tight, it is recommended to purchase imported configurations, because some domestic technologies do not meet the requirements, and foreign configuration machines have stable performance and less after-sales maintenance, which greatly improves work efficiency.

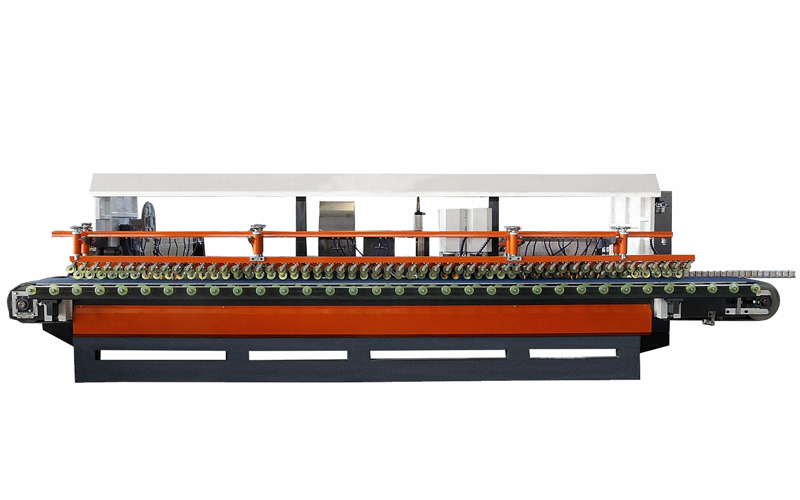

Zhejiang Haigong Machinery Co., Ltd. is famous China Stone Edge Polishing Machines Manufacturers and Stone polishing machines factory, set up in 1978 and it is located in TAIZHOU, a coast city in the Yangtze delta with an advanced economy and convenient transportation. We are always a global leader in stone processing machinery as our lifelong goal. We have been devoted to developing and producing various stone machinery for more than 30 years of history. Now with an area of 80,000 square meters, intelligent office building and 50,000 square meters modern standard factories contain welding, casting and another three production areas. It has become a high technology enterprise at the command of research, manufacture, selling and after-sales service to produce stone machinery professionally. We were awarded as one of the Top ten of CISE Chinese stone machinery, and also one of the ten top brands among Chinese stone machinery, and also passed CE certification and so on. Our major products are infrared bridge cutting machine, PLC automatic profile cutter, bridge edge grinding machine, bridge edge cutting machine, edge cutting and grinding machine and also wholesale stone edge polishing machines, line polishing machine, automatic washbasin polishing machine and so on which made by our under-company: ZHEJIANG HAIGONG MACHINERY CO.,LTD” with all the brand of ZHENGDA”.