AUTOMATIC BRIDGE CUTTING MACHINE ZDH-450A/600AX(90º)

Products

Contact Us

- Phone : 0086 13666863738

- Email : zhengda@cnzdkj.com

- Add:No. 199, Chuangye Avenue, Jiangnan Street, Linhai City, Taizhou City, Zhejiang Province.

Technical Parameter

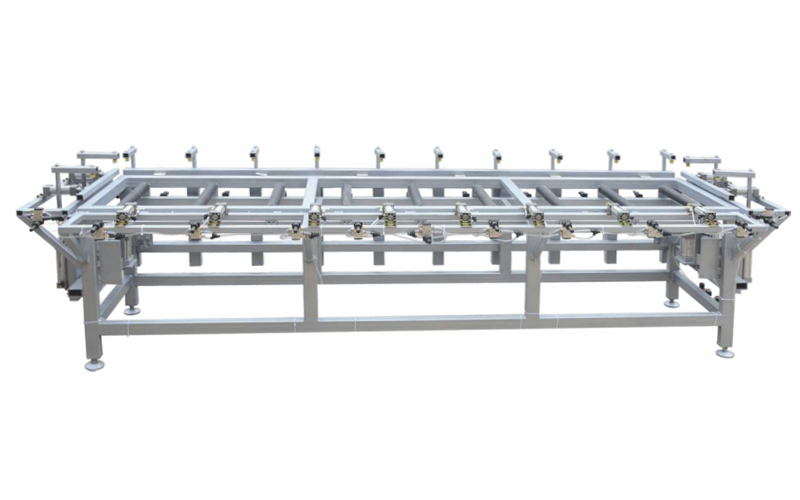

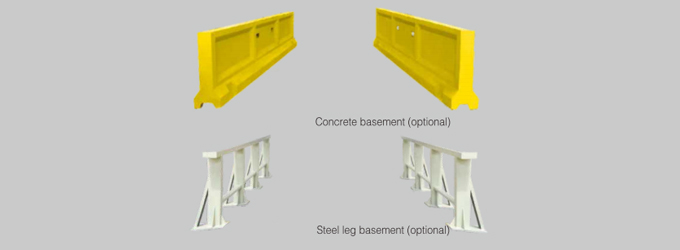

Structure

Processing photos

Processing video

MAJOR TECHNICAL PARAMETERS

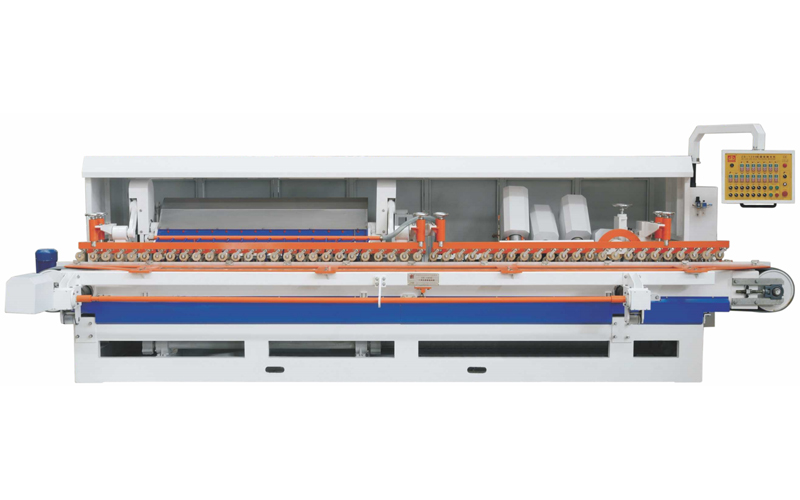

Item ZDH-450A/600AX(90º) Max.processing dimension 3200×2000×150mm Workstation rotation size 90º/360º Saw blade diameter Φ350-Φ600mm Main engine power 17/18.5kw Total power 22.2/23.7kw Outline dimension 6000×4500×3050mm Weight 5/5.5T Water consumption 3m³/h FEATURE AND FUNCTION

This equipment adopts guide movement with highly precision grinding and manual scraping, the main parts are processed by heat treatment, the main beam and side beam are smoothed by oil immersed lubricating. The surface of lift guide rails are plated hardware treatment.

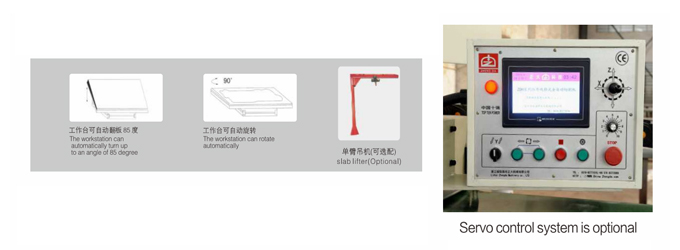

It adopts by infrared to cut, the cuting speed by inverter control to achieve stepless adjustment . the head movements, table tilt up, rotation and position are used hydraulic transmission to move. And the main parts are imported with high quality, it can be cut by manually and fuly automatic easily.

It adopts PLC programmable control system and touch screen operator and combined with high precision encode positioning.

The worktable is adopted at 90 degree rotation , and position at 360 degree, and there is no effect of the environment in stable using.

This machine is made of a good steel with high working accuracy and moving stable with long service life.

It is applicable to cut the valuable and large sized stone board for many specifications.

We established our production line to introduce the world-class production equipment for planer, grinding rails, large floor lathes, horizontal boring machine, CNC lathe, and other major processing equipment are from famous international equipment suppliers. Our major products are infrared bridge cutting machine, PLC automatic profile cutter, bridge edge grinding machine, bridge edge cutting machine, edge cutting and grinding machine and also arc edge polishing machine, line polishing machine, wholesale AUTOMATIC BRIDGE CUTTING MACHINE ZDH-450A/600AX(90º) and so on which made by our under-company: ZHEJIANG HAIGONG MACHINERY CO.,LTD” with all the brand of ZHENGDA”.

Contact Us

ZHEJIANG HAIGONG MACHINERY CO., LTD.

- Add:No. 199, Chuangye Avenue, Jiangnan Street, Linhai City, Taizhou City, Zhejiang Province

- Phone:0086 13666863738

- Tel:0086 (0)576 8571 5999

- Fax:0086 (0)576 8571 0711

- Web:www.haigongjixie.net

- Web:www.chinastonemachine.net

- Email:zhengda@cnzdkj.com

EN Mobile Version

CN Mobile Version